Burlington’s Thordon Bearings forms alliance on cash-saving, eco-friendly marine design

Published December 8, 2023 at 2:03 pm

Burlington-based Thordon Bearings and Finland’s Wärtsilä have teamed up to form the Blue Ocean Alliance to develop and promote the sterntube-less ship concept, a design that can save ship owners money while protecting the oceans from pollution.

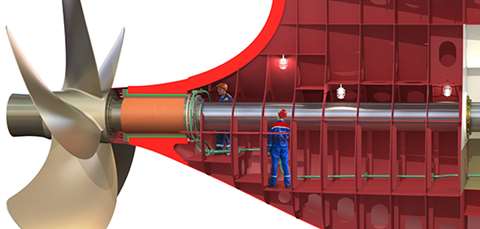

The concept of a ship design that does not require a sterntube and eliminates the need for oil-lubricated sterntube seals and bearings is considered revolutionary in the industry as it cuts the time of a bearing or seal replacement job from two weeks in dry dock to a single day while afloat.

More importantly, the concept requires zero environmentally damaging lubricating oil.

The Blue Ocean Alliance is bringing together centuries of maritime industry expertise with seawater-lubricated bearings pioneer Thordon – which began life in Hamilton more than 100 years ago – Helsinki-based systems integrator Wärtsilä, the School of Naval Architecture & Marine Engineering of the National Technical University of Athens (NTUA), naval architect Shanghai Merchant Ship Design & Research Institute (SDARI) and the classification society ABS, which championed the initiative in 2019.

ABS has already granted approval (in principle) to ship designer SDARI – in partnership with Thordon and NTUA -for the concept design of the sterntube-less vessel with Thordon’s COMPAC Split Seawater-Lubricated Aft Bearing.

Thordon, which was honoured last month at the International Bulk Journal Awards with the Environmental Protection Award (Marine) for its pioneering ThorPlas-Blue grease-free bearings, is calling the sterntube-less propeller shaft system design concept T-BOSS – Thordon-Blue Ocean Stern Space.

“The Blue Ocean Alliance brings together a formidable partnership to develop and further promote the concept. The fact that several ship owners have already shown interest in this solution is extremely encouraging,” said Thordon CEO Anna Galoni. “The T-BOSS concept introduces a new approach to a merchant vessel’s aft layout – removing the sterntube casing, employing seawater for lubrication and creating a dry chamber to permit in-water maintenance for the first time.”

The T-BOSS utilizes Thordon’s seawater-lubricated COMPAC propeller shaft bearing system and the Wärtsilä Enviroguard Seal, which requires no maintenance between planned overhauls of up to five years.

The key to the design, explained Galoni, is in the replacement of the vessel’s sterntube cooling tank with a dry irregularly shaped chamber, allowing for inspection and maintenance of a seawater-lubricated single bearing and seal from inside the ship, while afloat, without any need to withdraw the shaft.

“These innovations enable ship owners and shipyards to eliminate propeller shaft oil emissions, simplify maintenance and lower operational costs,” Galoni said.

inhalton's Editorial Standards and Policies advertising